2.3 Küttelahendused

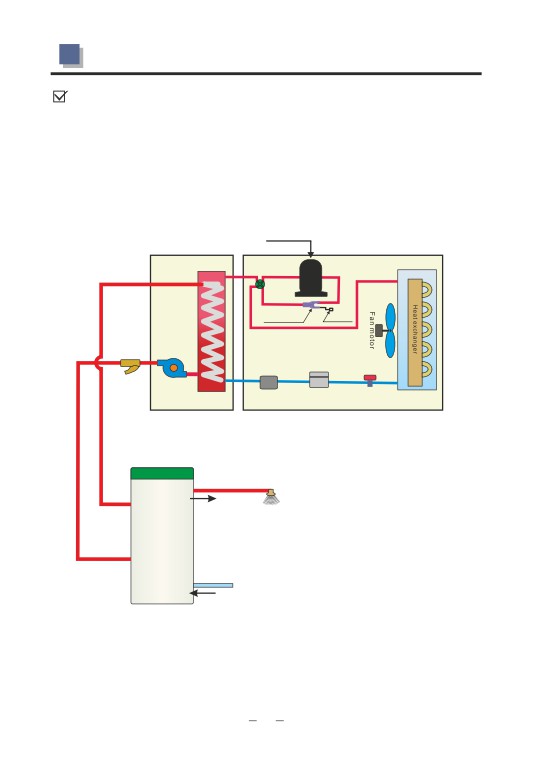

3: Põrandaküte ja eelsoendatud tarbevesi.

Tarbeveele on vajalik eraldi spiraal.

Eelsoendatud-

Tarbevesi

Pump1

Põrandaküte

Tarbevee sisend

Tühjendus

Põrandaküte ja eelsoendatud tarbevesi.

4: Maja küte ja soe tarbevesi.

Päikesekollektor

Soe tarbevesi (. .)

Pump 3

Toa Temp.1

El küttekeha.

E1

Radiaator

Pump 2

Põrandaküte

Toa Temp.2

Tarbevesi sisse

Tühjendus

Soojuspump Päikesekollektor

Küte ja soe tarbevesi

25

2.4 Installation

■ Indoor unit installation

For the installation of the indoor unit, please refers to the followings:

Locating

cardboard

1.Use the locating cardboard to

2.Drill the holes on the wall.

mark the positions of the indoor unit

on the wall.

Expansion bolt

3.Insert the expansion bolts (Terminal

4.Hang the indoor unit on the

diameter less than 16mm) into the

expansion bolts.

holes.

Note: The wall must strong enough to hang the unit on.

weather

enclosure

The refrigerant piping and signal cable

penetration

between indoor,outdoor unit should go

sleeve

through the wall by using a wall sleeve.

26

2.4 Installation

■ Outdoor unit installation

1. The unit must be located on a flat, solid, preferably cemented

surface.

2. when installing the unit, introduce a tilt of 1 cm/ m for rain water

evacuation

3. when installing the unit in harsh climatic conditions, sub-zero

temperatures, snow, humidity.., it is recommended to raise the unit off the

ground by about 20cm.

4.It is recommended to have a base with following size for these units:

5.Rubber vibration absorbing mountings are recommended.

6.When sitting the unit, take care to leave sufficient free space all around

it for carrying out maintenance.

2

3

1

NO

AVH-12V1D

AVH-24V1D

1

1028

1094

2

738

906

3

300

300

1. Fix the bracket on the wall with expansion bolts.

2. Place the outdoor unit on the bracket. A vibration absorber is

recommended to

reduce the noise of the outdoor unit.

3. Fix the unit to the bracket.

27

2.4 Installation

■ Wiring

Precaution:

1.It is recommended to use a suitable breaker for the heat pump and make

sure the power supply to the heater corresponds to the

specifications. Otherwise the unit might be damaged.

2.The power supply to the heat pump unit must be grounded.

3.Cable should be fixed tightly, to ensure it won't get lossen.

1.Take off the screw on the side of

2.Open the indoor unit.

the unit.

3. Take off the cable fixture and

4. Connect the power cable to the

insert the power cable through the

terminal block.

fixture(customer can choose

Please refers to the wiring diagram

which cable fixture is more

on the indoor unit.

convenient, the one on the top or

the one on the bottom of the unit).

28

2.4 Installation

5. Fix the cable with cable fixture, to

6. Take off the screw on the handle of

ensure it won't get lossen.

the outdoor unit.

7. Take off the small handle.

9. Connect the other side of the

power cable to the outdoor unit,

according to the wiring diagram.

10. Fix the power cable.

11. Wiring done!

29

2.4 Installation

■ Connection of refrigerant pipe

Connector for

Note: When vacuuming the system,

refrigerant pipe

please don't turn on the high/low pressure

valve. Otherwise refrigerant leakage

Connector of

High/Low

vacuum pump

pressure valve

1. Connect the refrigerant piping to the

2.Connect the other side of the

indoor unit.

refrigerant pipe to the outdoor unit.

3 . A vacuum pump and pressure

4 . Take off the copper nut on the high

gauge is needed. Connect the

pressure connector of the unit.

pressure gauge to the vacuum

Connect the other pipe of the pressure

pump.

gauge to the valuve as shown in the

picture. Open the pressure gauge and

start the vacuum pump.

30

2.4 Installation

5.Vacuum the unit for at least 15

6.Use a 5mm hex wrench to open two

minutes till negative value shown on

valves on the unit as shown in the

the pressure gauge. Turn off the

picture.

vacuum pump and install the cooper

nut back to the high pressure

connector.

Note:Small leakage may happen during the process.This is caused by

the shape change of the o-ring inside due the low temperature. Leakage

stops once the valves are fully opened.

7. Put the copper nut back. Tighten

them with a wrench.

It is recommended to check the leakage with some suds water

after installation.

31

2.5 Application of the extra sensor kit

■ Application of the extra sensor kit

When the customer use our

heat pump unit for house

heating purpose only, he can

connect this extra long

temperature sensor kit to our

wired controller, so the unit can

read the room temperature. In

this way, the unit can provide

hot water to the house heating

Size of the kit: 85*85*30 mm

system when the room

temperature doesn't get the set value, or stop providing hot water when

room temperature meets the set value.

How to install the room temperature sensor kit:

1.Take the short room

temperature sensor

out from the indoor

unit.

2. Open the box of the room temperature

sensor kit.

32

2.5 Application of the extra sensor kit

3.Put the short room temperature sensor

picked up from the indoor unit into the box.

4.Connect the room temperature to the extra

long signal cable, which packed inside the

accessories bag. And then connect the other

side of this extra long signal cable to the

connector inside the indoor unit.

Fixed! Now you can put the room

temperature sensor kit to wherever you want,

to read the room temperature there.

33

2.6 Control of external electric heater

■ Control of external electric heater

Customer can do as followings to connect the a external electric heater to

the unit:

1. Open the indoor unit.

2. Find the relay as marked in red below.

3. Connect the power or signal cable

from the electric heater, to this relay.

One cable should be connected to

position A, while the other cable should

be connected to any one of the

connectors at position B.

4. If according to our heat pump logic, the external electric heater should be

turned ON, our unit will send its signal to this relay, so to close the relay, to

start the electric heater. The maximum allowable current this relay can bear

is

30A.

If directly connect the power cable of the electric heater to our unit, please

refer to the wiring diagram-A in the next page.

If the maximum current of the electric heater is more than 30A, an extra

contactor is needed, please refer to the wiring diagram-B in the next page.

34

2.6 Control of external electric heater

WIRING DIAGRAM-A

WIRING DIAGRAM-B

35

2.7 Air purging

Piping connection figure

Drain pipe

1

Check Valves

2

Filter

city water

3 Shut-off valve

■ Air purging

Indoor unit

Water outlet

F4

Water inlet

F3

drainage

connector

F2

Filter

F1

(open)

(open)

Ball valve

(open)

City water

Outdoor unit

36

2.7 Air purging

The whole water system of this unit should be a closed water system.

Because of this, please purge the air inside as following after all the

water pipe connection work finished:

1.Open the water tap at the lowest level, so the air inside the sanitary water

system can be purged out by the pressure of water.

2.Open the filling valve to fill the whole water tank and the water system with

water (this process may take around 20 minutes).

3.Close all the valves when there is water coming out from the end of the

water system.

4.Air purging finished!

Please refers to the following figures:

If the water supply is cut off, the unit will show protection code on its screen.

The customer should cut the power off till the water coming again.

It is necessary to purge the air again when restart the unit after the water was

cut off.

37

2.8 Pre Start-up

■ Pre Start-up

Before starting up the unit, a certain number of verifications must be

performed on the installation to ensure that the unit will operate under the

best possible conditions. The check list below is not exhaustive and should

only be used as a minimum reference basis:

1.Make sure fan rotates freely.

2.Inspect all water piping for flow direction.

3.Verify all system piping is correct for operation as per installation

requirements.

4.Check voltage of the unit power supply and make certain voltage is within

authorized limitations.

5.Make sure the unit is properly grounded.

6.Check the presence of protective and breaking devices.

7.Check all electric connections for tightness.

8.Check all piping for leaks and air is well ventilated.

Unit Start-up

After ensuring all electric connections conform to the local regulations, follow

the Operation Instructions to start-up the unit.

After start-up the unit, if there is a abnormal sound, please shut off the power

supply immediately to ensure the safety of the unit.

38

3.1 Introduction of operation panel

■ Introduction of operation panel

ON/OFF

Timer

Confirm/

MODE

Key Lock

Down-regulation

Up-regulation

Display

Meaning

Function

Heating

When the unit works in heating mode ,

is ON.

Cooling

When the unit works in cooling mode , is ON.

Hot water

When the unit works in hot water mode , is ON.

Defrosting

When the unit works in defrosting , is ON.

Key lock

When buttons are locked ,

is ON.

Parameter

When parameter setting is activated ,

is ON.

setting

To display temperature, timer, parameter,

value or code

error code and so on.

The unit will clear its clock time when power

Time

failure happens.

When water temperature mode is activated,

Water temperature

is ON.

39

3.2 Operation instruction

When changing the set temperature,

Set temperature

is ON.

When timer function is activated,

Timer function

is ON.

■ Operation instruction

Standby

The unit is standby when it is fed with power.

※The unit will clear its clock time when

power failure happens. The customer needs

to set the time again.

ON/OFF

When the unit is standby, press to turn on

the unit. The unit will work in its last working

mode. Press again to turn off the unit.

※The unit will recover its latest working settings

automatically after power failure.

Mode selection

Keep on pressing button to choose water

temperature or air temperature as the set

temperature. When water temperature works

as the set temperature,

is ON;

When air temperature works as the set

temperature,

is OFF.

Mode selection

Press to choose the unit operation mode. It

comes in the sequence:

→Heating、

→

Cooling、

→ Hot water.

40

3.2 Operation instruction

Temperature setting

When the unit is ON, press once, the set

temperature increases by 1℃; press once,

the set temperature decreases by 1℃. Keep

on pressing or

, the temperature can be

increased or decreased by 5 ℃.

When changing the set temperature,

is

ON.

Parameter setting

When power is fed and unit is off , press or to

choose target Parameter.

Press to activate parameter setting process

when parameter flickers. User can set its value

with button or

; Press

again to confirm

the setting work: otherwise the setting Value

will not be saved. and the system will exit this

parameter Setting program automatically in 10 seconds, or by

pressing.

Parameter 1

Parameter 2

Parameter 3

Parameter 1 indicates the

Parameter 3 indicates the

This parameter has

local time. The time is

duration time for back light. It

no function in this

always presented in the

can be set to 00, 10, 20, and 30.

unit.

24-hour system

While 00 means the back light

is always ON, and 10, 20, and

30 means the duration time for

back light is 10 seconds, 20

seconds and 30 seconds.

41

3.2 Operation instruction

Timer function

To set the ON timer, press

button.

turns

on and blinks. Press

to set the timer in

hours, and to set the time in minutes. After it

is done, press

to confirm the ON timer

setting and enter the OFF timer setting, with

blinks. Set the OFF timer by pressing

and . After this done, press

to confirm

the OFF timer setting, with

shown on the

operation panel, indicating that the timer

setting is finished.

If the ON timer or OFF timer setting is not confirmed by

pressing

, the setting value is not saved.

The timer setting can be cancelled by keeping on pressing

,

with fading from the operation panel.

▲Timer ON

▲Timer OFF

Timer ON setting doesn't function

Timer OFF settings only functions

when the unit is working. It will be

after the unit starts. It can be

activated when the unit is turned

activated when the unit is

OFF.

turned ON.

Key lock

When the unit is ON, press

for

5 seconds, to

lock all the buttons, with shows. Press

for

5 seconds again, to unlock all the buttons.

42

4.1 Failure codes

■ Failure codes

Error

Causes

Ways to check and remedies

Codes

1.Wire connection between wired

1.Check whether the wire connection

controller and PCB open or

E0

gets loose. Fasten it.

short-circuited

2.Wired controller failure.

2.Change it.

1.Wire connection between wired

1.Check whether the wire connection

controller and PCB open or

E1

gets loose. Fasten it.

short-circuited

2.Wired controller failure.

2.Change it.

1. temp. sensor open or

1. Measure with a multimeter at 20K to check whether

short-circuited

it is shirt-circuited or open. If yes, change it..

2.Measure with a multimeter at 50K to check the

2.temp. sensor resistance

E2

sensor resistance. Take ambient temp. into

drifting

consideration. If it isdrifting, change it.

3.Temperature sensors not well

3.Check whether the sensor connection

connected to the wired controller.

gets loose. Fasten it.

1.Check whether the sensor connection gets loose.

Fasten it.

1. water inlet Temp sensor failure

2.Wire connection between wired controller and

indoor PCB open or short-circuited.

3.water inlet Temp sensor resistance drifting.

1.Check whether the sensor connection gets loose.

Fasten it.

2.water outlet Temp sensor

2.Wire connection between wired controller and

F2

PCB open or short-circuited.

failure

3.water outlet Temp sensor resistance drifting.

1、Check whether the sensor connection gets loose.

Fasten it.

2、Wire connection between wired controller and

3.Coil Temp sensor failure

indoor PCB open or short-circuited.

3、Temp sensor resistance drifting. temp. sensor

resistance drifting.

1、Check whether port gets loose. Fasten it.

F1

Communication failure

2、Change the PCB.

3、Change the outdoor PCB

Compressor drive failure、IPM

1.Check whether PFC transducer gets loose. Fasten

it.

F4

failure、IPM protection (overload)、

2.Change PFC transducer.

drive protection

F3

Current or Voltage detector failure

1.Change PCB

1、Check whether EEPROM gets loose.

F5

EEPROM failure

Fasten it.

2.Change EEPROM

43

4.2 Maintenance

1. Check the water flow of the unit

Too highr coil Temp in heating

2. Too high ambient and water Temp. Reduce the set

water Temp.

1.Check the water flow of the unit

Too high pipe Temp in cooling

2.Too low ambient and water Temp.Increase the set water

F6

Temp.

1.Check the water flow of the unit.

Over-current protection

2.Too high (low) ambient, and too high(low) set water

Temp. Decrease or increase the set water Temp.

1.Check the voltage of the power supply.

F7

Too high or too low voltage

2.Change the outdoor PCB

1.Check the pressure of the system

F8

Pressure switch failure

2.Change the pressure switch

1.Check whether EEPROM gets loose.

F9

EEPROM failure

Fasten it.

2.Change outdoor EEPROM

Ambient temp. sensor failure

1、Check whether the sensor connection gets loose.

Fasten it.

Fb

Pipe temp. sensor failure

2、Wire connection between wired controller and PCB

open or short-circuited.

Compressor discharge temp.

3、Temp sensor resistance drifting.

sensor failure

1.Measure the high (low) pressure switch with a

System protection caused by too

multimeter to check whether it is shirt-circuited or open.

Fc

high(low) pressure

If yes, change it.

2.Check the water flow of the unit.

1.Check the ambient Temp sensor.

System protection caused by the

2.Check whether the ambient Temp is too high(low) for

Fd

working (Ambient lower than -1℃or higher than 65℃ in

ambient Temp.

cooling, lower than -25℃ or higher than 33℃ in heating).

■ Maintenance

1.It is forbidden to change the inner structure and wiring of the unit. Otherwise

injury of person or unit damage might happen.

2.If the unit fails to work properly, please cut the power supply immediately.

The maintenance work must be performed by qualified people.

3.“Failure check list” in this manual is helpful to find out and fix the

failure of the unit.

4.After long time running, the evaporator coil may get dirty, which will

affect the performance of the unit. It is suggested to clean the surface

of the coil occasionally.

44

4.2 Maintenance

Maintenance of the electric components

indoor

1、Cut off the power supply.

2 . Open the doorofindoor unit and then take off the screws around the

electrical box.

3.Do the maintenance of the electrical parts.

Electrical box

outdoor

1.Cut off the power supply.

2.Take off the screws on the front panel, and take away the front panel.

3.Take off the screws on the right side panel, and take away the right side

panel.

4.Do the maintenance of the electric parts.

5.After done, install the right side panel and front panel back.

Figure 1

Figure 2

Opening view of

the unit

45

4.2 Maintenance

Condenser Coil

The condenser coils donot require any

special maintenance, except when they are

clogged by paper or any other foreign bodies.

Coil

Cleaning is by washing with detergent and

water at low pressure, and then rinsing with

clean water:

1. Before cleaning, make sure the unit is

off.

2. Inner of the unit must be cleaned by qualified person.

3. Donot use gasoline, benzene, detergent etc. to clean the unit. And

donot spray with insecticide. The unit may be damaged. The cleanser

special made for air conditioner cleaning is recommened.

4. Spray air conditioner cleanser into the coils. Let the cleanser sit

for

5

8 minutes.

~

5. Then, spray the coil with clean water.

6. An old hairbrush works well for brushing surface dirt and lint off the

fins. Brush in the same direction as the slots between the fins so the bristles

go between the fins.

7. After cleaning, use a soft and dry cloth to clean the unit.

Gas Charging

even under severe operating conditions. If your unit needs recharging,

then it has a leak, and adding refrigerant will not solve the problem. The leak

must be located and repaired.

1.Gas charging must be performed by

qualified person.

2.One can find out whether the system has

enough refrigerant inside by checking the low

pressure inside the system.

46

4.3 Trouble shooting

Cleaning of the filter

The Y-filter must be cleaned occasionally to ensure the water flow of the

water system.

Drainage

please follow the instruction to drain out the water :

1.Shut off all the water inlet.

2.Drain out the water in the water system by opening the water tap at the

highest position of the system.

3.Drain out the water in the tank by opening the valve to the drainage

connector on the tank.

4.Drain out the water in the heat pump system.

2

1

4

3

47

4.3 Trouble shooting

■ Trouble shooting

Malfunction

Possible Causes

Remedies

1.Power supply cut-off

1.Check the power supply.

2.Check whether the unit is well grounded.

2.Power fuse burnt out

If yes, check the fuse and change it if

necessary.

Heat pump

unit is out

3.If the protection is caused by the failure,

of operation

3.Unit protection

please refers to the failure code list and

fix the failure before restarting the unit.

4.Loose connection of

4.Check the connections.

power cables

5.Compressor failure

5.Replace the compressor.

1.Fan motor wire loose

1.Check the wire connections.

Fan is out

2.Fan motor burnt

2.Change the fan motor.

of operation

3.Fan motor relay fails

3.Change the fan motor relay.

1.Coil fins are dirty

1.Clean the evaporator coil

2.Remove any object that blocks the air

Low heating

2.Air inlet/outlet blocked

circulation of the unit.

capacity

3.Inspect the unit for leakage and fix it if any.

3.Lacking of refrigerant.

Discharge all refrigerant and charge the unit

again with right amount.

Too high noise

1.Check the water filling device. Fill the

1.Lacking of enough water.

from the water

system with enough water.

pump, or no

2.Air inside the water system.

2.Purging the air out.

water flow

3.Check all the valves to ensure they are

when the

3.Water valve closed.

water pump

fully opened.

is running.

4.Filter is blocked

4.Clean the filter

1.Discharge all refrigerant and charge the

1.Too much refrigerant.

unit again with right amount.

2.Discharge all refrigerant and charge the

Too high

2.Air inside the refrigerant system.

unit again with right amount.

compressor

discharge

3.Check the water flow of the system. Use

pressure

3.Too small water flow

a bigger pump if necessary.

4.Check the value of the water temperature

4.Too high water temperature

sensor, to ensure it works properly.

1.Drier filter blocked

1.Change the drier filter

Too low

2.Expansion valve failure

2.Check and replace the expansion valve.

suction

3.Inspect the unit for leakage and fix it if any.

pressure

Discharge all refrigerant and charge the unit

3.Lacking of enough refrigerant

again with right amount.

48

4.3 Trouble shooting

1.Check the position and value of the coil

1.Coil temperature sensor failure

Unit can

temperature sensor. Replace it if necessary.

not defrost

2.Remove any object that blocks the air

properly

2.Air inlet/outlet blocked

circulation of the unit. Clean the evaporator

coil occasionally.

The following phenomenon may not be problems. Please contact with a

professional maintenance staff.

NO

Malfunction

Possible Causes

1.May be caused by compressor restart protection. The interval time

The unit is

of compressor restart is 3 minutes.

1

not running

2.Please check whether the circuit breaker, the power supply is open.

When the unit is running, if sound of the running water can be heard

The unit is

2

from the system of the unit, it is the sound of running of the

too noisy

refrigerant. This is not a failure.

Check whether the air inlet/outlet is blocked. Check whether the

The unit output

temperature setting is too high in cooling mode, or too low in heating

3

mode. Check whether the room is too big. Check whether there are

is too small

too many people inside the house when unit is in cooling operation.

49

5.1 Wiring diagram

AVH-1 2 V1D outdoor unit

Compressor

Fan

Condensor

4-way

heater

motor

valve

FM

C

heater

~

Y/G

CN423

COMP

CN426

CN428

CN429

CN427

CN414

CN405

CN404

CN417

CN418

HEAT1

4-WAY

HEAT2

FAN

DC+ DC-

CN413

connect to

ACN

the indoor unit

AC-L

CN409

Y/G

G

CN407

Y/G

RY401

G

CN410

PCB Board

L

P7B

P10-3

P10-2

P10-1

P6B

CN5

CN408

DC-

W

V

U

DC+

N

CN403

CN401

CN402

CN423

Y/G

CN411

Module board

S

DC+

DC-

CN5B

CN415

CN416

CN406

G

6

CN8C

Outdoor PCB

5

P7C

L.E.V

DC-

L

AC-L AC-N

P13

P14

P11

P12

DC+

L

P6C

PFC Reactance

AVH-1 2 V1D indoor unit

Power supply

CN209

CN204

PCBBOARD

Cn211

CN212

CN201 CN203 CN202 CN213

Y/G

CN206

CN205

CN207

CN208

Y/G

50

1. Wiring diagram

AVH-2 4 V1D outdoor unit

FM~

C

N

L

H

P5

P6-2 P7-2

CN414

DC+ DC-

N

P0-3

P4

RY401

P0-2

P0-1

P1

CN5

AC-L

P7B

P10-3 P10-2

P10-1 P6B

DC- W

DC+

P2

V U

AC-N

CN3

CN2

CN1

CN7

S

P3

DC+

DC-

P6-1

P7-1

CN5B

6

CN8C

5

P7C

DC-

P14 P11 P12

L AC-L AC-N

P13

DC+

L

P6C

PFC REACTANCE

AVH-2 4 V1D indoor unit

Power supply

CN209

CN204

PCB Board

Cn211

CN212

CN201 CN203 CN202 CN213

Y/G

CN206

CN205

CN207

CN208

Y/G

TAKE CARE !

This diagram is correct at the time of publication. Manufacturing changes could

lead to modifications. Always refer to the diagram supplied with the product.

51